7/29 Wire Load Capacity: Comprehensive Guide to Ampacity, Specifications & Applications

For every electrician, contractor, and hardware shop owner, the right electrical wire is the backbone of any reliable installation. It’s not just about getting the job done; it’s about ensuring safety, efficiency, and long-term performance. Among the most common and versatile options in Pakistan, the 7/29 wire stands out. But what exactly does this designation mean for its load capacity, and how can you ensure you’re choosing a truly high-quality cable?

This comprehensive guide from Life Cables will demystify 7/29 wire, helping you make informed decisions that safeguard your projects and reputation.

7/29 Wire? Demystifying Its Core Specifications

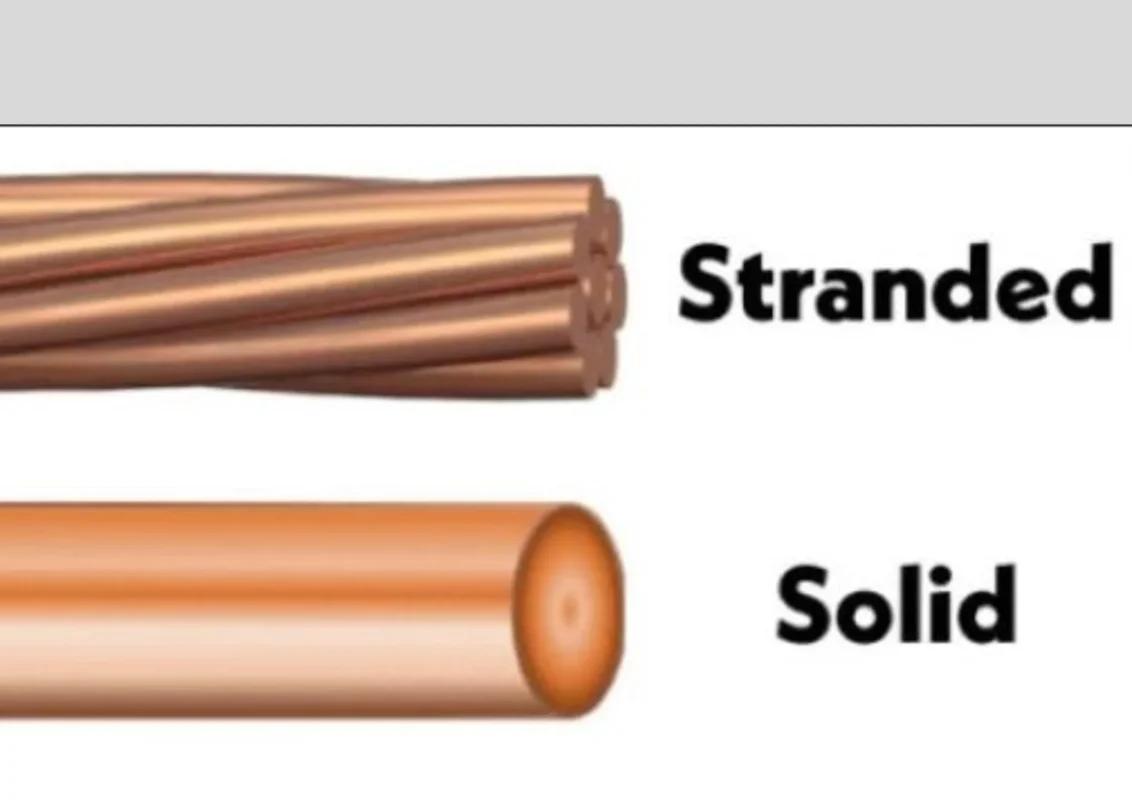

The designation “7/29 wire,” also correctly written as 7/.029″ or 7/0.029″, refers to a specific type of stranded electrical wire. This imperial British Standard (BS 2004 compliant) cable construction provides essential insights into its properties.

The “7” and the “.029”: A Deeper Dive into Construction

The “7” in 7/29 indicates that the wire is composed of seven individual strands of copper. This multi-strand design is crucial, as it significantly enhances the wire’s flexibility and strength compared to a solid core wire, making it easier to handle and install, especially where bends or movement are required.

The “.029” refers to the diameter of each individual strand in inches. Converting this to millimeters yields approximately 0.7366 mm, aligning with other sources stating the individual strand diameter is approximately 0.74 mm.

Important Clarification

While “29” is sometimes ambiguously associated with AWG (American Wire Gauge) size, an AWG 29 wire has a much smaller diameter of approximately 0.0113 inches (0.287 mm). For the 7/29 wire to achieve its commonly cited total cross-sectional area, the 0.029 inch / 0.74 mm strand diameter interpretation is the accurate and relevant one.

Metric Equivalent: Understanding 2.5mm²

For professionals working with metric units, it’s vital to know that the 7/29 wire size typically corresponds to a total conductor cross-sectional area of 2.5 mm² (square millimeters). This makes it equivalent to a standard 2.5 mm² wire commonly used in metric electrical systems.

The Critical Factor: 7/29 Wire Load Capacity (Ampacity)

Ampacity is the current-carrying capacity of a wire. It’s the maximum amount of current a wire can safely handle continuously without exceeding its designated temperature limit, which could lead to deterioration, insulation damage, or even fire hazards.

Typical Ampere Rating Explained

The current-carrying capacity (load capacity) for 7/29 wire typically ranges from 15 to 20 amperes. For Life Cables’ 7/.029″ Single Core Premium Copper/Std, the stated Ampere Rating is 21 Amps. This makes it suitable for various low- to medium-power applications.

Calculating Power Capacity (Watts) for Your Applications

To understand the power a 7/29 wire can support, you use the fundamental electrical formula: Power (Watts) = Voltage (Volts) x Current (Amps).

Given a typical current capacity of 20 amps:

| Voltage | Power Capacity |

|---|---|

| 240 volts | 4,800 watts |

| 120 volts | 2,400 watts |

| 220 volts (Pakistan standard) | 3,300 to 4,400 watts |

| 230 volts | 3,450 to 4,600 watts |

To calculate the total load requirement for a circuit, sum the wattages of all planned devices and divide by the system voltage. This gives you the required current. Always include a safety margin, typically by adding 20% to your calculation, and ensure your circuit breaker capacity aligns with this total load.

Key Factors Influencing Ampacity and Safety

The published ampacity ratings are guidelines. Several factors can influence the actual safe current a wire can carry:

- Temperature: Higher ambient temperatures can reduce the wire’s current-carrying capacity. Our cables are rated for a temperature range of -20C˚ to 70C˚

- Installation Conditions: How the wire is installed—such as being bundled with other wires, run in conduit, or exposed to open air—significantly affects its ability to dissipate heat and thus its ampacity

- Wire Length and Voltage Drop: Longer wire runs can experience voltage drop, which can affect the effective load capacity by reducing the voltage available at the load

- Insulation and Conductor Material: Life Cables guarantees 99.99% pure oxygen-free copper conductor and high-quality PVC insulation for optimal performance and safety

Exceeding the wire’s current capacity can lead to overheating, insulation damage, and potentially dangerous fire hazards or short circuits. It is always recommended to consult relevant electrical codes and standards for specific applications to ensure safe and proper wiring practices.

Versatile Applications: Where 7/29 Wire Shines

Thanks to its balanced flexibility, conductivity, and appropriate load capacity, 7/29 wire finds widespread use across various sectors.

Residential and Commercial General Wiring

The 7/29 wire is a cornerstone for general house wiring, including:

- Lighting circuits, fan points, and standard wall sockets in homes

- Main room wiring and connecting power from distribution box to individual rooms

- Room main and UPS supply wiring in offices and commercial buildings

- Extension cables and portable electrical devices (prevents breakage from repeated bending)

Specialized and DC Applications

The 7/29 wire is also suitable for a range of specialized applications:

- Solar Panel Installations: The 7/0.29 (1MM) cable is used for DC (Direct Current) applications, particularly in solar power systems for connecting various components

- Automotive Applications: Ideal for vehicle wiring systems, connecting headlights, tail lights, horn systems, and audio systems, with good resistance to vibration damage

- Control Systems & Robotics: Suitable for intricate wiring in control panels and automation systems

- Instrumentation and Signal Transmission: Used for connecting sensors and electronic components

Why Quality Matters: Beyond Just Load Capacity

For electrical professionals, compromising on wire quality is a risk that can lead to significant problems down the line. A low-quality cable can not only degrade the performance and lifespan of appliances and equipment but also dramatically increase electricity bills due to higher heat generation and energy loss.

Life Cables understands that wires are the “lifeline of all buildings”. Our commitment to quality ensures:

Uninterrupted Current Flow & Efficiency

Our high-quality, 99.99% pure copper conductors provide very low electrical resistance, ensuring current flows smoothly without excessive heat generation or voltage loss. This translates to reduced electricity costs and optimal operation of all connected machinery and gadgets, potentially lowering your power bill by 20% to 30%.

Prioritizing Safety & Compliance

We manufacture all our cables, including 7/29, to strict international standards such as British Standard Specification (BSS 2004, BSS-6004) and International Electro-Technical Commission (IEC) standards. This guarantees safety for buildings and compliance with industry codes. Our cables are routinely tested by independent laboratories like PCSIR and UET, in addition to rigorous in-house tests.

Durability & Longevity

Our wires are designed to work for generations. With a typical service life of 20 years or more, our 7/29 wire reduces the need for frequent replacements, saving time and money for your projects.

Choose Life Cables for Unmatched Quality

Ready to invest in the reliability your projects deserve?

Call: +923328153200

Selecting the Right Wire: Beyond 7/29

While 7/29 (2.5mm²) is an excellent choice for general wiring, heavier loads or specific applications may require different cable sizes. Understanding these distinctions is crucial for proper electrical design and safety.

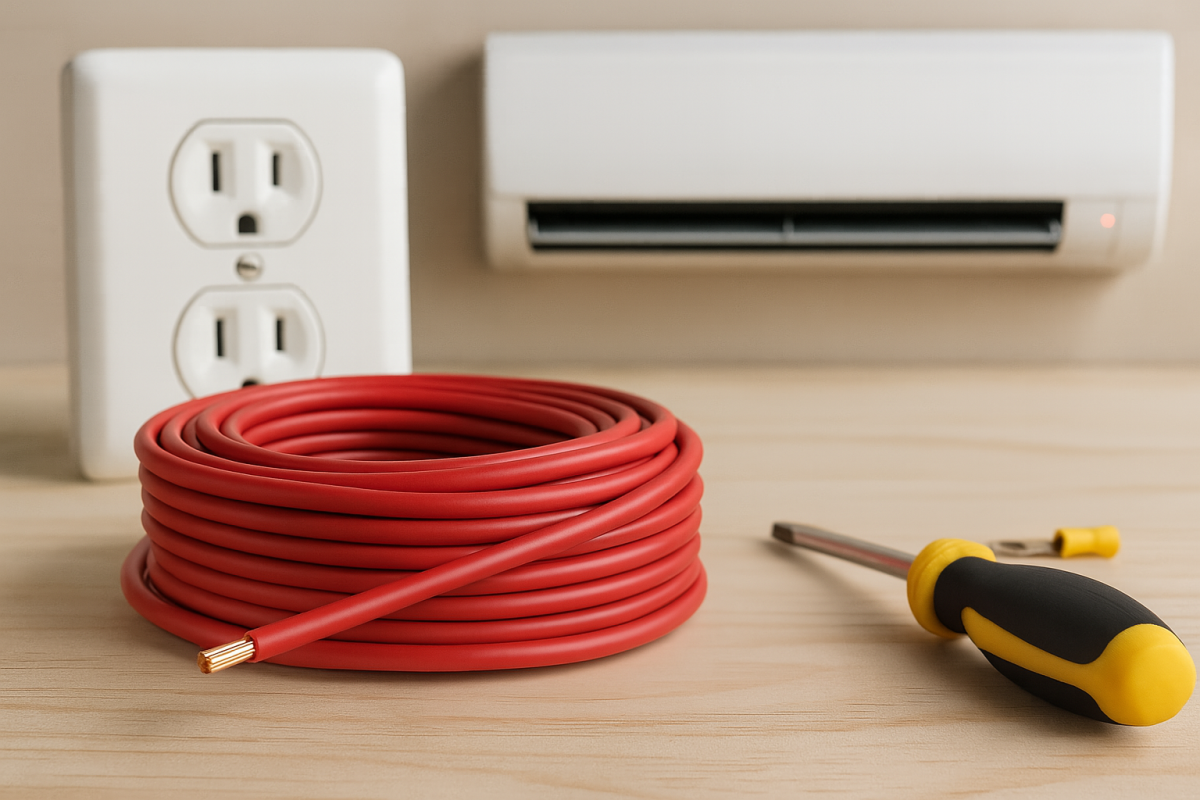

Important Question: Can I use 7/29 wire for a 1.5-ton AC?

Generally, 7/29 wire (2.5 mm²) is not recommended for a 1.5-ton AC unit. For appliances drawing significant current, a larger wire size like 7/44 (6 mm²) is extensively used and recommended to ensure safety, prevent overheating, and maintain optimal performance. For even heavier loads or longer runs, a 7/64 (16 mm²) wire might be required.

Important Considerations for Proper Wire Sizing

- Always Refer to Local Electrical Codes: These codes and guidelines exist to ensure safety and compliance, and must be followed when selecting and installing wires

- Match Original Wire Specifications: When replacing existing wiring, precisely matching the original wire’s specifications is crucial to avoid potential hazards

- Consider Insulation Material: Different types of 7/29 wire are available with various insulation materials like PVC or rubber

- Confirm Wire Size Accurately: A standard round gauge tool is commonly used to measure wire size

7/29 Wire Price in Pakistan: Your Investment in Reliability

The price of 7/29 wire in Pakistan can vary depending on several factors, including fluctuating market costs of copper, brand reputation, insulation quality, and the supplier.

Life Cables: Premium Quality, Transparent Pricing

As a leading manufacturer with over five decades of experience since 1968, Life Cables offers competitive manufacturer-direct pricing. Our 7/29 cable price in Pakistan normally ranges from Rs. 7,000 to Rs. 14,000 for a standard 90-meter coil made with 99.99% pure copper. This range reflects our commitment to providing premium quality at affordable rates.

Get Your Custom Quote Today!

For the most up-to-date and accurate rates on 7/29 wire, or for custom quotes on bulk quantities, always contact Life Cables directly.

WhatsApp us: +923328153200

Frequently Asked Questions (FAQs)

Q1: What does 7/29 wire mean?

A: 7/29 wire is a stranded wire composed of seven individual strands. The “29” refers to the diameter of each strand as 0.029 inches, which is approximately 0.74 mm. It is a classic imperial British Standard (BS 2004 compliant) electric cable.

Q2: How many mm is a 7/29 wire?

A: The total cross-sectional area of a 7/29 wire is typically 2.5 mm² (square millimeters). Each individual strand has a diameter of approximately 0.74 mm.

Q3: What is the load capacity of 7/29 wire?

A: The 7/29 wire typically has a current-carrying capacity (ampacity) ranging from 15 to 20 amperes. Life Cables’ 7/.029″ Single Core Premium Copper/Std has an Ampere Rating of 21 Amps. This capacity can vary based on factors like ambient temperature, installation conditions, and wire length.

Q4: What are the common uses of 7/29 wire?

A: 7/29 wire is widely used in residential wiring for lighting, switches, outlets, and UPS supply. It’s also common in commercial wiring, automotive applications, control systems, robotics, telecommunications, low-voltage power cables, and instrumentation/signal transmission. It is also suitable for DC applications in solar power systems.

Q5: What is the difference between a 7/0.29 and a 2.5mm wire?

A: A 7/0.29 wire (where 0.29 is understood as 0.029 inches) is an imperial cable consisting of 7 strands, each with a diameter of 0.029 inches (~0.74 mm). A 2.5mm² wire refers to a cable with a total conductor cross-sectional area of 2.5 square millimeters. In many contexts, 7/0.29 wire is considered the imperial equivalent of a 2.5mm² wire due to their similar total cross-sectional areas and current-carrying capacities.

Q6: How many amps does 7/29 wire support?

A: As mentioned, 7/29 wire is estimated to support around 15 to 20 Amps, with Life Cables specifying 21 Amps for its product.

Q7: Can I use 7/29 wire for a 1.5-ton AC?

A: No, 7/29 wire (2.5 mm²) is generally not recommended for a 1.5-ton AC unit. For this type of appliance, a larger wire size like 7/44 (6 mm²) is extensively used and recommended to ensure safety and optimal performance.

Q8: What is the standard coil length for 7/29 wire?

A: A standard coil of 7/29 electrical wire is typically 90 meters in length.

Q9: Is 7/29 wire suitable for solar power systems?

A: Yes, the 7/0.29 (1MM) cable is primarily used for DC (Direct Current) applications, which is typical in solar power systems for connecting various components where solar panels produce DC electricity.

Final Thoughts: Invest in Reliability with Life Cables

Choosing the right 7/29 wire is a critical decision that impacts the safety, efficiency, and longevity of your electrical projects. By prioritizing quality, certifications, and proven performance over just the lowest price, you ensure peace of mind for yourself and your clients.

Think of selecting the correct electrical wire like building a robust bridge. The 7/29 wire is a critical component, and just as a bridge needs to be designed for the specific weight and flow of traffic it will bear, your wire must be precisely matched to the electrical load it will carry. An undersized wire is like a bridge too weak for its load, prone to overheating and potential failure, while oversizing can be an unnecessary cost. With the right knowledge of 7/29 wire’s specifications and capabilities, you can confidently build strong, secure, and safe electrical pathways that last for generations.

Life Cables stands as your reliable partner, offering premium 7/29 copper wire manufactured to international standards, backed by rigorous quality control, and available at transparent, manufacturer-direct prices.

Connect with an Expert Today!

Ready to empower your projects with premium quality 7/29 wire?

Call Life Cables for Free Consultancy: +92 332 8153200

Check out more blogs by just clicking here.

For the most current pricing and technical specifications, please contact Life Cables directly.