Cables for Photovoltaic Installations-2026 Comprehensive Blog

🔌 1. Types of Cables in Photovoltaic Installations

a. PV (Photovoltaic) Cables

- Use: Connect solar panels to each other and to the combiner box.

- Standards: Often comply with EN 50618 or TÜV 2 Pfg 1169/08.2007.

- Features:

- UV and ozone resistant

- Weatherproof and flexible

- Double insulation

- Halogen-free

- High-temperature resistance (typically -40°C to +90°C, up to 120°C short-term)

b. DC Cables

- Use: Carry direct current from panels to the inverter.

- Type: Single-core, usually tinned copper for better corrosion resistance.

- Color: Usually red (positive) and black (negative)

c. AC Cables

- Use: Carry alternating current from inverter to the distribution board or grid.

- Type: Multi-core, often 3-core or 5-core with earthing.

d. Earth (PE) Cables

- Use: For grounding/earthing metal parts of the system.

- Color: Green/yellow

e. Communication Cables

- Use: Connect devices like inverters, charge controllers, and monitoring systems.

- Type: RS485, Ethernet, or fiber optic depending on the system

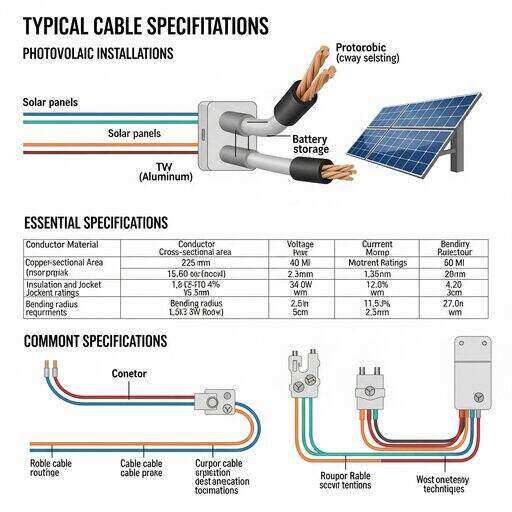

📏 2. Typical Cable Specifications

| Feature | Value / Description |

|---|---|

| Voltage Rating | 600/1000 V AC, 900/1800 V DC |

| Conductor Material | Stranded tinned copper or bare copper |

| Insulation/Sheath | XLPE, EPR, or cross-linked polymer (halogen-free) |

| Temperature Range | -40°C to +90°C (continuous use) |

| UV Resistance | Required for outdoor use |

| Flame Retardant | Yes (as per IEC 60332-1 or similar) |

| Certifications | EN 50618, IEC 62930, TÜV, CE |

Cables for photovoltaic (PV) installations are specialized electrical cables designed to meet the unique and demanding requirements of solar power systems. Unlike standard electrical cables, PV cables must withstand harsh outdoor environments while ensuring efficient and reliable transmission of power from solar panels to inverters and the grid.

Key Characteristics and Requirements of PV Cables:

- UV Resistance: This is paramount as PV cables are constantly exposed to direct sunlight. Their outer sheath and insulation are made from materials like cross-linked polyethylene (XLPE) or similar polymers that do not degrade under prolonged UV radiation, preventing cracking, brittleness, and loss of insulation integrity.

- Temperature Resistance: Solar installations experience extreme temperature fluctuations, from scorching heat to freezing cold. PV cables are designed to operate reliably across a wide temperature range, typically from -40°C to +90°C (and sometimes higher for short-circuit conditions), without compromising electrical or mechanical properties.

- Weather and Moisture Resistance: They must be resistant to rain, humidity, snow, and ice. The robust outer jacket provides excellent protection against moisture ingress, preventing insulation breakdown and short circuits. Many are rated AD8 for water submersion.

- Ozone Resistance: Ozone, a common atmospheric gas, can degrade conventional cable materials. PV cables are specifically formulated to resist ozone, ensuring long-term durability in outdoor settings.

- Mechanical Durability: While often static, PV cables need to be robust enough to withstand mechanical stresses such as abrasion, impacts, and bending during installation and throughout their 25-year (or more) lifespan. Some variants even offer rodent protection.

- High Voltage and Current Handling: PV systems generate DC (Direct Current) power, often at higher voltages than typical residential AC systems (e.g., up to 1.5 kV DC between conductors, and 1.8 kV DC between conductor and earth for modern systems). Cables must be sized and insulated to safely handle these DC voltages and the continuous current generated by the solar panels, minimizing voltage drop and power loss.

- Flame Retardancy and Halogen-Free Properties: In the event of a fire, it’s crucial that cables do not propagate flames or emit toxic fumes and dense smoke. Many PV cables are designed to be Low Smoke Zero Halogen (LSZH or LSOH), meeting standards for fire performance, which is vital for safety, especially in rooftop installations or where people are present.

- Conductor Material: Typically, tinned copper is used for its superior conductivity, corrosion resistance, and flexibility. Tinning the copper further enhances its resistance to oxidation. While less common for module interconnections, aluminum conductors are also used in larger DC power transmission lines due to cost and weight benefits.

- Insulation and Sheath Materials: Cross-linked polyethylene (XLPE or XLPO) and ethylene propylene rubber (EPR) are common choices for insulation and outer sheathing due to their excellent electrical, thermal, and environmental resistance properties. These materials often offer double insulation for enhanced safety.

- Flexibility: While sometimes rigid depending on the gauge, PV cables, particularly those for module interconnections, need sufficient flexibility to facilitate easy routing and installation around panels and mounting structures.

Relevant Standards and Certifications:

To ensure safety, performance, and longevity, PV cables must comply with specific international and national standards. Key standards include:

- EN 50618 (Europe): This is a harmonized European standard specifically for PV cables, superseding previous standards like PV1-F. Cables complying with EN 50618 are often marked H1Z2Z2-K. It mandates low smoke zero halogen properties, flexible tin-coated copper conductors, and robust cross-linked insulation and sheath.

- IEC 62930 (International): A core international standard outlining requirements for the construction, performance, and testing of PV cables.

- UL 4703 (USA): An Underwriters Laboratories standard for photovoltaic wire and cable products in the United States, covering safety and performance criteria.

- IEC 60811: Defines test methods for insulation and sheathing materials.

- IEC 60332-1: Pertains to fire resistance testing.

- IEC 60754 and IEC 61034: Specify limits on smoke density and toxic gas emissions.

Choosing certified, high-quality PV cables from reputable manufacturers is crucial for the long-term efficiency, safety, and reliability of any solar power installation.

Read other blogs and guides for more comprehension on https://lifecables.com/