7/29 Wire for 1.5 Ton AC: Complete Wiring Guide for Safe Installation

As a leading Pakistani cable manufacturer, Life Cables is committed to providing expert insights and high-quality solutions for all your electrical needs. Today, we’re addressing a crucial question for electricians, contractors, and hardware shop owners: What is the optimal “7/29 wire for 1.5 ton AC” unit? Choosing the right wire size isn’t just about functionality; it’s about ensuring safety, efficiency, and longevity for your installations and your clients’ peace of mind.

7/29 Wire for 1.5 Ton AC: Is It the Right Choice for Your Installation?

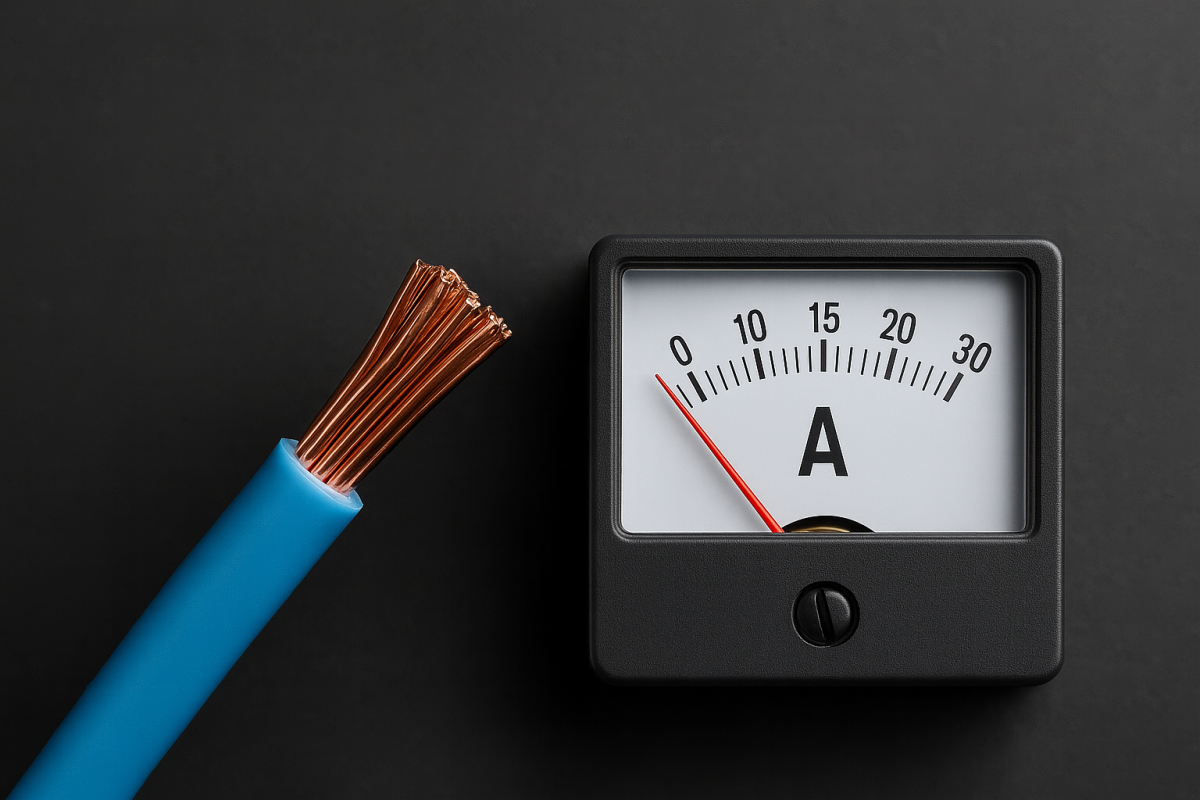

When it comes to wiring a 1.5-ton AC unit, the “7/29” wire frequently comes up in discussions. This designation refers to a stranded wire with 7 individual strands, each 29 thousandths of an inch in diameter. In terms of current carrying capacity, a 7/29 wire is roughly equivalent to a 2.5 sq mm wire.

For a 1.5-ton AC unit, most experts suggest using a 2.5 mm² wire as a minimum requirement. This size is generally considered capable of safely carrying the running current required by the AC unit without immediate overheating.

Why Consider 4 mm² Wire Instead?

However, for enhanced safety and performance, many professionals also recommend a 4 mm² wire for a 1.5-ton AC. The 4 mm² wire offers significant advantages:

- Better handling of sudden current surges: AC units, especially non-inverter types, experience a large inrush current (2 to 3 times the normal load current, potentially 25-30 amps for half a second) during startup. A thicker wire can better absorb this initial electrical shock.

- Reduced voltage drop: For longer wire runs, voltage can drop, impacting AC performance. A 4 mm² wire minimizes this more effectively than a 2.5 mm² wire. For runs over 30 meters, a 4 sq mm wire is especially recommended.

- Prevention of overheating: A larger wire gauge provides better heat dissipation, reducing the risk of the wire overheating, which can lead to energy loss and potential electrical hazards.

- Enhanced safety margin: Choosing a larger wire provides an added safety margin, ensuring reliable operation even under varying conditions.

While a 2.5 mm² (14 AWG) wire is often sufficient, a 4 mm² (12 AWG) wire is a safer and more robust choice for ensuring the long-term reliability and efficiency of your 1.5-ton AC installation. Copper wire is generally recommended due to its superior conductivity and heat dissipation properties compared to aluminum.

Understanding 1.5 Ton AC Electrical Requirements

To make an informed decision about wire size, it’s essential to understand the electrical demands of a 1.5-ton AC unit.

Current Draw and Power Consumption

A 1.5-ton AC unit typically draws around 8-10 amps of current during normal operation. For units running on a 240-volt supply, the power consumption is around 4,500 watts, translating to about 18 to 20 amps. However, inverter ACs may have a maximum current reaching up to 10 amps.

Circuit Breaker Sizing

The circuit breaker protects the electrical circuit from overcurrent. For a 1.5-ton AC, the recommended MCB (Miniature Circuit Breaker) rating is usually between 16 to 20 amps. This range provides adequate capacity to handle both the running current and the occasional inrush current when the compressor starts. It’s crucial that the breaker is appropriately sized for the AC’s current draw.

Wire Gauge and Current Capacity

The wire’s ability to safely carry current without overheating is called its ampacity. Here’s a general guideline for AC wire sizes and capacities:

| Wire Size (mm²) | AWG (American Wire Gauge) | AC Capacity (Tons) | Max. Current (Amps) | Typical Usage |

|---|---|---|---|---|

| 2.5 mm² | 14 AWG | 0.75 – 1.5 Ton | 18-22 Amps (capacity) / 8-10 Amps (1.5-ton AC load) | Minimum recommended for 1.5-ton AC, especially for shorter runs and efficient units. Sufficient for 8-10A draw. |

| 4.0 mm² | 12 AWG | 2.5 Ton | Better for current surges, voltage drops, and overheating | Recommended for extra safety, longer runs (>30m), and to minimize voltage drop and energy loss. |

| 6.0 mm² | 10 AWG | 3-5 Ton | 25.5 Amps (for 3-ton) | For heavier loads, such as a 3-ton AC. Can be used for two 1.5-ton ACs on separate circuits. |

Note: This table provides general guidance. Always refer to the specific AC unit’s data plate for its maximum current draw and the manufacturer’s installation requirements.

Factors Influencing Wire Size Selection

Beyond just the AC tonnage, several other critical factors influence the appropriate wire size:

Wire Length (Run)

Longer wire runs increase resistance, leading to greater voltage drop and potential performance issues. For installations exceeding 30 meters, a 4 mm² wire is strongly recommended to minimize voltage drop and ensure efficient operation.

Ambient Temperature

Higher ambient temperatures necessitate a larger wire size to safely dissipate heat and prevent overheating.

Wire Material

Copper wire is the preferred choice for AC units due to its excellent electrical conductivity and efficiency, preventing overheating better than aluminum. Using aluminum wire for 1.5-ton AC is not recommended as it heats up more, leading to rigidity loss and loose connections.

Installation Method

Wires enclosed in trunking or conduits may perform differently than those run on perforated cable trays due to variations in heat dissipation.

AC Type (Inverter vs. Non-Inverter)

Inverter ACs gradually increase loading, prohibiting sudden high starting currents. A 1mm or 1.5mm wire might work for inverter ACs, but for non-inverter ACs with high starting currents (2-3 times normal load), a minimum of 2.5 mm² wire is applicable.

Life Cables: Your Trusted Partner for AC Wiring

At Life Cables, we understand that quality wiring is the backbone of any safe and efficient electrical installation. Our copper wires are engineered to meet stringent standards, providing the reliability and performance demanded by professional electricians and contractors.

Explore Our Range

Explore our range of high-quality copper wires designed for AC units and various power loads:

- View 7/29 Wire Pricing and Specifications (Add internal link to 7/29 product page)

- Discover our 4mm² Wire Range for Enhanced Safety (Add internal link to 4mm product page)

Order Your Wires Today!

Ready to secure the best wiring for your next project?

Get an instant quote or place your order now!

WhatsApp Life Cables (+923328153200)

For bulk orders or specific project requirements, our team is here to assist you.

Frequently Asked Questions (FAQs)

Q1: Which wire is required for a 1.5-ton AC?

For a 1.5-ton AC unit, a minimum wire size of 2.5 mm² (or 14 AWG) is generally recommended. However, many experts advise using a 4 mm² wire for extra safety, as it can better handle sudden current surges, voltage drops, and overheating, especially for longer wire runs.

Q2: Can I connect a 1.5-ton AC with a 1.5 mm wire?

It is generally not recommended to use a 1.5 mm wire for a 1.5-ton AC, especially for non-inverter models. While a 1.5 mm wire has a maximum capacity of around 12 amps, a 1.5-ton AC can draw 8-10 amps during normal operation and significantly more (2-3 times) during startup. Using an undersized wire can lead to excessive heating, energy loss, and fire hazards. For inverter ACs, a 1.5 mm wire might be better than 1mm, but 2.5mm is still generally preferred.

Q3: What does “7/29 wire” mean, and what is its load capacity in amps?

The “7/29” designation refers to a stranded wire composed of 7 individual strands, each 29 thousandths of an inch (or 29 gauge) in diameter. This type of wire is roughly equivalent to a 2.5 sq mm wire in terms of current carrying capacity. A 2.5 sq mm wire is typically rated to safely carry 18-20 amperes.

Q4: How much current is needed for a 1.5-ton AC?

A 1.5-ton AC unit typically requires 8 to 10 amps of current for safe operation. Some sources indicate a running current of about 18 to 20 amps at 240 volts for a power consumption of around 4,500 watts. During startup, the compressor can draw a momentary surge of 25-30 amps.

Q5: What size wire is typically used for 220V AC units?

For 220V (or 230V/240V) AC units, the appropriate wire size depends on the current (amperage) the circuit will carry. As a general guide:

- A 20A circuit typically uses #12 AWG copper wire (equivalent to 4 mm²)

- A 30A circuit generally requires #10 AWG copper wire (equivalent to 6 mm²)

- For a 1.5-ton AC with a typical 8-10 amp draw, a 2.5 mm² (14 AWG) wire is often considered sufficient, but 4 mm² (12 AWG) is recommended for better safety and performance

Longer wire runs may require a larger gauge to minimize voltage drop.

Q6: Is solid or stranded wire better for AC?

For AC wiring, especially for connections that might experience movement or vibration, stranded wire is generally preferred over solid wire. While solid wire can offer higher current capacity for the same thickness, stranded wire’s multiple thin strands provide greater flexibility, making installation easier and reducing the risk of breakage over time. Stranded wire also offers more surface area for heat dissipation due to air gaps between strands, which can translate to more efficient cooling.

Q7: Why does AC wiring typically have three wires (phase, neutral, and earth)?

AC wiring typically uses three wires for safety and proper functionality:

- Phase (Hot) Wire: Carries the active electrical current from the power source to the AC unit

- Neutral Wire: Provides the return path for the current, completing the circuit. Ideally, the neutral wire should be the same size as the hot wire

- Earth (Ground) Wire: This is a crucial safety component. It provides a direct path for fault currents to safely dissipate into the earth, protecting users from electric shock in case of an electrical fault or insulation failure. For a 1.5-ton AC, a 2.5 mm² or larger wire for earthing is recommended, though some suggest 1.5 sq mm or even 0.75mm. Always ensure proper earthing for safety.

A Final Thought

Think of your AC unit as a high-performance vehicle and the wiring as its fuel line. Just as a powerful engine needs a strong, clear fuel line to deliver consistent performance and prevent overheating, your 1.5-ton AC requires properly sized, high-quality copper wiring to operate efficiently and safely. Undersizing can lead to a “choke point” in the system, causing strain, inefficiency, and potential hazards. Always prioritize the robust solution for lasting peace of mind.

For expert advice and to ensure your electrical installations meet the highest safety and performance standards, always consult with a qualified electrician and adhere to local electrical codes.

Contact Life Cables Today +923328153200 Get expert advice and premium quality wiring for your AC installations

For the most current pricing and technical specifications, please contact Life Cables directly.