🔌Tinned Copper-Industrial Cables-2026 Comprehensive Blog

In the complex and demanding world of industrial operations, the choice of wiring and cable is paramount to ensuring safety, efficiency, and longevity. While bare copper has long been the gold standard for electrical conductivity, it often falls short in harsh environments. This is where the powerful combination of Tin and Copper steps in, offering an indispensable solution for modern industrial applications.

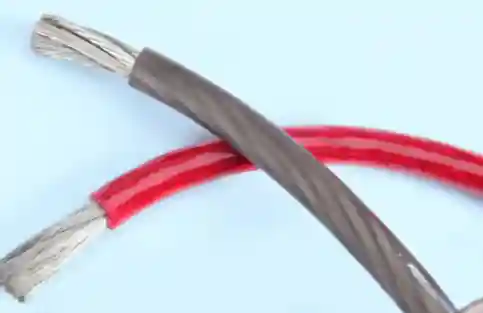

Industrial wires and cables featuring a tin coating over a copper conductor—commonly referred to as tinned copper—are a superior choice for any project that demands maximum resilience and reliability in challenging conditions. This specialized construction leverages the superb conductivity of copper while mitigating its vulnerability to environmental degradation.

What is Tinned Copper Wire and Cable?

At its core, a tinned copper wire is a copper conductor—the material responsible for carrying the electrical current—that has been coated with a thin layer of tin. This tinning process is typically achieved through hot-dipping the copper into molten tin or via an electroplating method.

The result is a wire that inherits the inherent benefits of both metals:

- Copper’s unparalleled electrical conductivity and tensile strength.

- Tin’s exceptional resistance to oxidation and corrosion.

This seemingly simple protective layer makes a profound difference in the wire’s long-term performance, making tinned copper an essential component across a spectrum of demanding industries.

🛡️ The Crucial Benefits of Tin-Plated Copper

The decision to use tinned copper often translates directly into significant long-term cost savings and enhanced operational reliability. Here are the primary advantages that make tin-plated copper cables the material of choice for industrial settings:

1. Superior Corrosion and Oxidation Resistance

The most critical benefit of tinning is the protective barrier it creates. Bare copper, when exposed to moisture, humidity, and oxygen, is susceptible to oxidation. This process forms copper oxide, which manifests as a green or black tarnish. Unfortunately, copper oxide is an electrical insulator, which increases the wire’s resistance, degrades performance, and can eventually lead to system failure and overheating.

The tin coating prevents this direct contact, effectively shielding the copper from corrosive elements like:

- Moisture and high humidity

- Saltwater (especially crucial in marine and offshore environments)

- Sulfur and other aggressive industrial chemicals

By slowing down the oxidation process, tinned copper wires maintain their optimal electrical performance and integrity for a much longer period.

2. Extended Longevity and Durability

Due to the enhanced resistance to environmental damage, tinned copper cables boast a significantly longer service life compared to bare copper. In aggressive environments, this extended lifespan translates to reduced maintenance, fewer costly replacements, and minimal system downtime. For infrastructure projects designed to last decades—such as utility projects, solar farms, and wastewater treatment facilities—this durability is invaluable.

3. Enhanced Solderability

The tin coating significantly improves the wire’s ability to be soldered. Soldering bare copper requires aggressive fluxes and can be challenging due to surface oxidation. Since tin is the primary component of most electronic solder, the tin coating allows the solder to flow smoothly and bond quickly and firmly to the wire. This results in cleaner, stronger, and more reliable electrical connections, which is a major benefit for manufacturing and assembly processes in electronics and complex industrial machinery.

4. Stable Performance in High Temperatures

While copper is susceptible to accelerated oxidation at high temperatures, the tin coating provides an additional layer of thermal protection. This helps tinned copper cables maintain their performance and integrity in elevated temperature environments, such as inside engine compartments, heating elements, and power distribution panels, often increasing their maximum continuous operating temperature rating.

🏭 Key Industrial Applications

The robust properties of tinned copper make it indispensable across a multitude of industries where environmental challenges and reliable performance are constant concerns.

- Marine and Offshore: Perhaps the most demanding environment, saltwater is highly corrosive. Tinned copper is the standard choice for boat wiring, offshore platforms, and coastal infrastructure to resist salt corrosion and humidity.

- Automotive and Aerospace: Used extensively in wiring harnesses, battery cables, and control systems. The vibration and temperature extremes in these sectors necessitate the superior durability and corrosion resistance of tinned conductors.

- Renewable Energy: Solar arrays and wind turbines are exposed to the elements 24/7. Tinned copper cables are essential for connecting solar panels (PV wires) and within turbine systems, protecting against moisture and UV degradation.

- Industrial Automation and Robotics: In factories, tinned stranded conductors are used in highly flexible cables for robotic arms. The tinning acts as a lubricant between strands, reducing friction and metal fatigue, which extends the flex life of the cable.

- Wastewater Treatment and Chemical Plants: These facilities are rife with corrosive chemicals and persistent moisture. Tinned copper cables ensure that vital instrumentation and power systems remain operational despite constant chemical exposure.

Choosing Your Industrial Cable: Tinned vs. Bare Copper

When specifying wire and cable for an industrial project, the decision between bare and tinned copper boils down to the application environment.

| Feature | Bare Copper | Tinned Copper |

| Primary Use | Dry, protected, and standard indoor environments (e.g., grounding) | Harsh, wet, high-humidity, or corrosive environments |

| Corrosion Resistance | Low—prone to oxidation/verdigris in moisture | High—tin coating acts as a protective barrier |

| Solderability | Good, but requires more preparation (flux) | Excellent—easy, clean, and strong solder joints |

| Longevity | Good in dry conditions | Excellent—extended service life in all conditions |

| Initial Cost | Lower | Higher (due to the tinning process) |

For critical systems in harsh or outdoor conditions, the higher initial investment in tinned copper offers an unmatched Return on Investment (ROI) by minimizing maintenance costs and preventing catastrophic failures. It is a choice for long-term reliability and peace of mind.

By understanding the unique benefits of the tin-copper blend, industrial professionals can select cables that not only meet performance requirements but also withstand the relentless rigours of their operating environment, ensuring the smooth and secure flow of power for years to come.