🔥Fire Alarm Cables Function (in simple words)-2026

The Unsung Heroes: Your Complete Guide to Fire Alarm Cables

When it comes to fire safety, the focus is often on visible components like smoke detectors, pull stations, and alarm horns. However, the true backbone of any reliable fire detection and alarm system lies in the fire alarm cables. These seemingly simple wires are the lifelines that ensure critical signals travel instantly, activating alarms and saving lives and property. Choosing the correct cable type, ensuring proper installation, and adhering to strict regulations are non-negotiable for a truly effective system.

This comprehensive guide will help you understand the essential role of these cables, the different types available, and why selecting the right product is vital for public safety and regulatory compliance.

Why Fire Alarm Cables are Critical to Safety

Fire safety systems are complex networks designed to act immediately upon detecting a fire. Every component—from the control panel to the notification appliances—must communicate flawlessly. Fire alarm cables transmit the power and data signals between these components.

In the event of a fire, the environment is hostile: heat, flame, and smoke can quickly compromise standard electrical wiring. If a cable fails, the entire system can be rendered useless. This failure could mean delayed detection, non-sounding alarms, or the inability of emergency response systems to activate—catastrophic outcomes in a life-or-death situation.

High-quality, fire-rated cables are specifically engineered to withstand extreme conditions, maintaining their circuit integrity for a specified time. This sustained functionality is what allows building occupants to evacuate safely and gives first responders the necessary information to manage the emergency.

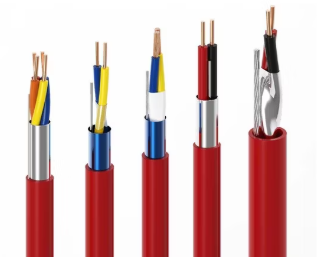

Understanding Key Fire Alarm Cable Types

Choosing the right cable is paramount, and selection depends heavily on the installation location and local building codes. In the U.S., the National Fire Protection Association (NFPA) and Underwriters Laboratories (UL) define specific cable ratings, which are often classified based on their smoke and flame-spread characteristics:

1. FPL (Fire Power-Limited) Cable

- Application: General purpose fire alarm use.

- Compliance: The most basic fire alarm cable. It is non-plenum rated, meaning it can only be used in non-air-handling areas (like surface wiring) or within approved raceways (conduit).

2. FPLR (Fire Power-Limited Riser) Cable

- Application: Vertical runs between floors, shafts, or risers.

- Compliance: Designed to prevent the vertical spread of fire from floor to floor. The ‘R’ stands for ‘Riser.’

3. FPLP (Fire Power-Limited Plenum) Cable

- Application: Horizontal installations in air-handling spaces, such as drop ceilings or under-floor spaces (plenums) used to move environmental air.

- Compliance: This is the most stringent fire rating. ‘P’ stands for ‘Plenum.’ FPLP cables are engineered to have very low smoke-producing and flame-spread characteristics, crucial because air-handling spaces can rapidly distribute smoke throughout a building.

Beyond Ratings: Fire Survival Cables

For critical systems that must remain operational during a fire to assist in evacuation (like emergency lighting, voice communication, or smoke control fans), standard fire alarm cables may not suffice. Here, Fire Survival (Fire-Resistant) Cables are required.

These specialized cables are often insulated with materials like silicone and mineral insulation and are tested to maintain electrical circuit integrity for an extended duration (e.g., 2 hours). These are distinct from basic fire alarm cables and are specified for the most critical life-safety circuits.

The Chemistry of Safety: Materials Matter

The core function of a fire cable is tied directly to its construction materials:

- Conductor Material: Copper is the industry standard due to its excellent electrical conductivity and reliability. While aluminum is sometimes used for cost-effectiveness in very long runs, copper offers superior performance.

- Insulation and Jacket: The outer layers are the first line of defense. Many modern fire alarm cables utilize Low Smoke Zero Halogen (LSZH) materials. When standard PVC (polyvinyl chloride) insulation burns, it releases thick, black smoke and toxic, corrosive gases (halogens). LSZH jackets significantly reduce these harmful emissions, improving visibility for evacuation and limiting damage to sensitive electronic equipment.

Essential Best Practices for Installation and Maintenance

A high-quality cable is only as good as its installation. Poor wiring practices can undermine the best product, leading to signal degradation or outright failure.

Installation Compliance

- Adherence to Codes: Always install cables that meet the specific rating requirements (FPL, FPLR, FPLP) for their physical location in the building, as mandated by NFPA 72 (National Fire Alarm and Signaling Code) and local authorities.

- Proper Routing: Cables should be routed away from sources of electromagnetic interference (EMI) which could corrupt data signals. Using shielded versions (e.g., FPLP Shielded) can help maintain signal integrity in noisy environments.

- Avoid Damage: Protect cables from physical damage. Do not pull them with excessive force, which could stretch or compromise the insulation.

Regular Inspection and Testing

Fire alarm cables, like all system components, degrade over time. Routine maintenance is crucial:

- Visual Inspection: Check for visible damage, kinks, or signs of wear, especially in areas subject to movement or environmental stress.

- System Testing: Conduct regular, documented tests of the entire fire alarm system. This ensures that the circuits connected by the cables are functioning correctly and communicating effectively with the control panel.

The Cost of Compliance vs. The Value of Life

While fire alarm cables may represent a small fraction of a building’s total construction cost, their role in life safety is immeasurable. Opting for cheaper, non-compliant, or lower-rated cables can result in expensive re-installation, failed inspections, or, most critically, system failure during an actual fire event.

Investing in UL-listed, compliant fire alarm cables is an investment in the safety of building occupants, the preservation of property, and the longevity of your fire safety infrastructure. It is the cornerstone of a system you hope you’ll never need, but that absolutely must work when you do.

For this kind of informative blogs, visit Life Cables Blogs.