MEDIUM VOLTAGE CABLES

A complete range of MV cables developed under the most stringent international standards.

RHVhMVh

Medium Voltage cables for special applications.

TSLF

Cable for fixed installations.

Life Cable: Powering the Future with Medium Voltage Solutions

At Life Cable, we specialize in high-quality medium voltage (MV) cables designed to meet the demands of today’s power distribution systems. Our team of seasoned experts develops and manufactures a comprehensive range of MV cables that ensure efficient and reliable energy transmission across various industries. Operating within voltage ranges typically from 1 kV to 36 kV, our cables are trusted for their performance, durability, and safety. We also provide technical guidance for MV cable selection, logistics, and after-sales support to guarantee complete customer satisfaction.

Frequently Asked Questions (FAQ) – Medium Voltage Cables

What defines a medium voltage cable?

Medium voltage cables are designed for power distribution systems, capable of handling voltages typically between 1 kV and 69 kV. These cables are essential in industrial, utility, and commercial installations.

What are the main characteristics of MV cables?

MV cables are constructed with robust materials and engineered for reliability. They typically feature high-quality insulation, durable conductors, and are tested for electrical, thermal, and mechanical performance.

How do I choose the right MV cable for my needs?

Selecting the right MV cable involves evaluating:

Voltage requirements

Installation environment and ambient temperature

Cable run length

Insulation and conductor materials

Our technical team can assist in identifying the best solution for your specific application.

What materials are used for MV cable conductors?

MV cable conductors are usually made of copper or aluminum. Copper offers superior conductivity, while aluminum is valued for its light weight and cost-effectiveness.

Which insulation materials are commonly used?

The most widely used insulation materials include:

XLPE (Cross-linked Polyethylene)

EPR (Ethylene Propylene Rubber)

PVC (Polyvinyl Chloride)

These materials are chosen based on performance, flexibility, and environmental compatibility.

Are Life Cable MV cables fire-retardant?

Yes. Many of our MV cables are fire-retardant, halogen-free, and designed to meet international fire safety standards. For example, our X-VOLT® AL RHZ1 (AS) cable complies with:

EN 50399 (fire propagation)

IEC 60332-1 (flame propagation)

EN 60754-1/-2 (low emission of corrosive gases)

EN 61034 / IEC 61034 (low smoke density)

It is CPR rated Cca-s1b, d2, a1, ensuring top-tier fire safety.

How are MV cables tested for quality and reliability?

MV cables undergo extensive factory testing, including:

Electrical: dielectric strength, partial discharge, insulation resistance

Mechanical: tensile strength, flexibility, elongation

Thermal: aging tests to simulate long-term use

These tests confirm the durability, safety, and efficiency of our cables.

What standards must MV cables meet?

Our MV cables are designed in compliance with IEC 60502-2, ensuring reliability and performance in power generation, distribution, and select transmission systems.

How often should MV cables be maintained?

Routine inspections are essential. Follow a preventive maintenance schedule to monitor for signs of wear or damage, based on manufacturer recommendations and industry standards.

What are the safety concerns with MV cables?

Potential hazards include:

Electric shock

Arc flash

Fire risk

Proper installation, regular inspections, and use of PPE help mitigate these risks.

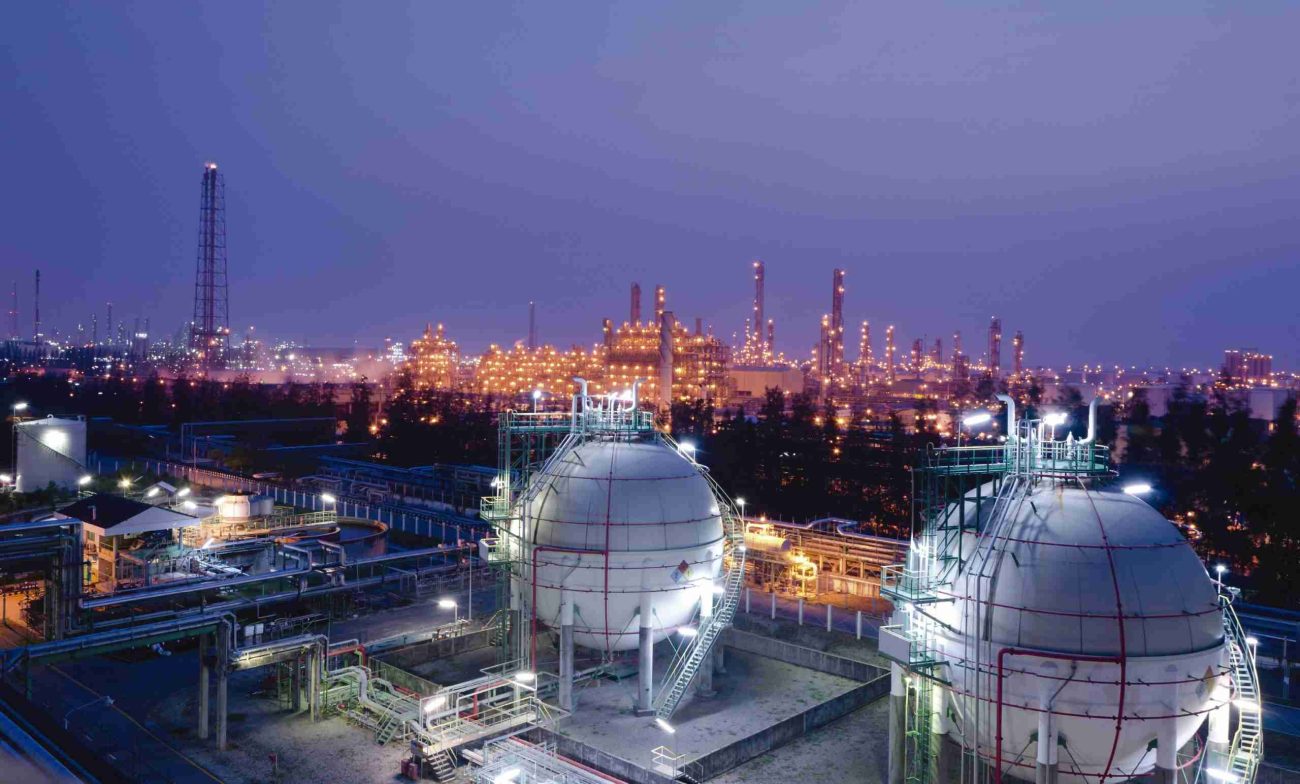

Where are medium voltage cables commonly used?

MV cables are ideal for:

Power distribution systems

Industrial plants

Renewable energy projects

Data centers

Are MV cables suitable for underground use?

Yes, MV cables are widely used in underground installations for added protection and reduced outage risks. Proper trenching, insulation, soil condition assessment, and protection layers ensure long-term performance.

What is a utility cable?

A utility cable is a type of MV cable used in electrical grid infrastructure, transferring power from generation sources to commercial, residential, and industrial users.

Which MV cables are best for industrial plants?

Industrial facilities require MV cables that can power heavy equipment and withstand harsh environments. Life Cable’s industrial-grade MV cables are engineered to resist:

Oil and chemical exposure

High temperatures

Mechanical stress

What about MV cables for renewable energy?

MV cables used in solar and wind energy systems are designed to handle variable voltages, harsh weather, UV exposure, and long-distance transmission with high efficiency and minimal losses.

How are MV cables used in transport infrastructure?

MV cables are essential in powering:

Electric railways

Subway systems

Airports

These installations require cables that are flame-retardant, low smoke, and abrasion-resistant to meet strict safety regulations.

Are MV cables chemically resistant?

Yes, our MV cables are made with materials selected for high chemical resistance, protecting them from hydrocarbons, solvents, and corrosive agents commonly found in industrial environments.

If you need expert advice or a tailored MV cable solution, the Life Cable technical team is here to help.

Contact us today to power your project with confidence and reliability.